Cannabis vaping needed a full-service hardware manufacturer with products designed for CBD and THC oils.

By Timothy S. Donahue

When the cannabis industry began to take off in the U.S., vaping became a popular way to consume cannabinoids. However, many of the devices used to vape nicotine products did not work as well with the more viscous cannabinoid oils, especially THC and cannabidiol (CBD). There was a massive need for high quality vaping products that were specific to the fast-growing cannabis industry.

The Blinc Group started in 2017 to provide industry-specific vaping hardware to cannabis companies in Canada, the U.S. and Europe, according to co-founder and CEO Arnaud Dumas de Rauly. The company offers off-the-shelf products that can be fully customized and creates bespoke products. Dumas de Rauly says Blinc Group isn’t a cannabis company; it’s a technology company that serves the cannabis industry. Blinc Group provides every level of service from product design and customization to compliance testing, manufacturing, shipping and logistics.

When the legal cannabis industry began to grow and more states legalized marijuana in some form, it wanted to separate itself from the nicotine vaping industry. There was little crossover between products. To Dumas de Rauly, who honed his skills in nicotine vaping hardware, it was baffling that no one was applying the knowledge gained in nicotine vaping to cannabinoids. He says that the cannabis industry today is in the same situation the nicotine vaping industry was in two or three years ago.

“It’s becoming more accepted by regulators, by the general public. However, I can see the cannabis industry making some of the same mistakes that nicotine vaping had made … such as marketing to kids. That is going to bite our industry in the ass over the next couple of years, especially when all of this becomes federally legal,” said Dumas de Rauly. “We’re going to be really frowned upon if we are using cartoons on our packaging, if we don’t use proper standards.”

In regulatory matters, the cannabis industry was trying to reinvent the wheel. Instead of using manufacturing standards and regulation that had been developed in electronic nicotine-delivery systems (ENDS), the cannabis industry wanted to create its own standards. When the industry started developing its own way of analyzing product emissions, Dumas de Rauly said he had had enough.

“We already have these standards in nicotine vaping. We can already use that basis and then just add some components we’ll be testing for that are specific to the terpenes that are specific to more viscous extracts, that are specific to cannabinoids. We already have a base,” he explains. “Radioactive components, for example. It’s something that seems logical. It’s in the nicotine vaping standards. We’ve got to make sure that there are no radioactive materials in there. That’s very easy. You just translate over to cannabis. Why the heck won’t we do it? Testing for aldehydes, heavy metals is stuff we’ve already been doing in nicotine vaping for years.”

Be on the Blinc

The same couldn’t be said for the hardware. While standards and regulation could be carried over from the nicotine vaping industry, hardware needed to be specific to cannabis. Eric Newman, director of sales for Blinc Group, says the THC industry in the beginning used hardware designed for nicotine but soon shifted to specific cannabis vaping products. Newman said to get the cannabis industry comfortable developing its own hardware was an educational experience.

“Different clouds work well with different types of products. Customer experience is something that we take seriously. For us, it was coming from a product perspective and a knowledge and educational perspective as well. We needed to teach the end user that one device or one product is better than the other and why they should use one product over another.”

Newman says that more companies are moving toward open systems and that is expected to continue moving forward. He said that Blinc Group is dedicated to passing along its knowledge across all stakeholders and getting more people talking about best practices and standard operating procedures [SOPs]. “I think it’s education first then proving that what you’re educating actually works,” says Newman. “Then you open up the network to the masses.”

A good example of a hardware change to accommodate cannabis products is the move away from poly-type or plastic cartridges, according to Newman. He says Blinc Group now uses strictly glass cartridges.

“The whole market hasn’t switched to that model, and we’re pushing the market into, from a quality and safety perspective, going to all-glass type cartridges,” he says. “The next step to that process is actually happening already. We’re making full ceramic cartridges, making full glass cartridges. Except for the inner components that still have to have some metal and ceramic cores—but it’s happening in front of us where we’re seeing those type of products. Unfortunately, Blinc Group hasn’t found any that fit our model, but there’s certainly a revolution happening already, and I think Blinc Group’s ahead of the curve on it.”

Dumas de Rauly attributes much of the Blinc Group’s success to the emphasis it placed on safety and compliance throughout the EVALI crisis of 2019 and the Covid-19 pandemic. Even outside investors are starting to notice. In early January, Blinc Group successfully raised $1.5 million in bridge funding.

“Our team navigated 2019’s vape crisis helping set standards and advise regulators on testing and compliance, and last year, the company saw our best quarter yet amid the Covid-19 pandemic as the industry learned the benefits of safety and traceability,” said Dumas de Rauly. “We have shown that we are a resilient company that puts consumers first, which has made all the difference.”

In just over a year, Dumas de Rauly and his two partners managed to turn their company into a business generating approximately $1 million in revenue, adding an additional five team members in the process. By 2019, the company was grossing over $4 million in revenue and had 15 employees. In 2020, Blinc Group more than tripled its orders with more than 330 percent year-over-year growth.

The technology company seemed to have a knack for expanding in an increasingly difficult regulatory landscape. “I don’t have the exact numbers yet, but I know in terms of sales orders, we hit $14.2 million in 2020,” said Dumas de Rauly. “We have increased our team to 21 members, and we are really excited about our future in this unique and exciting industry.”

Blinc of an eye

The Blinc Group specializes in standards and quality. The company was created to help the cannabis industry comply with Canada’s robust regulatory requirements through the highest quality testing and supply chain standards. Canada legalized recreational marijuana in 2017.

Dumas de Rauly and his two Blinc Group co-founders, Givi Topchishvili and Alexander “Sasha” Aksenov, who also serves as chief innovation officer, had the collective experience needed to change nearly every aspect of how the cannabis industry was operating, from standards and other regulatory needs to lobbying, manufacturing and even sales. Topchishvili is an entrepreneur, investor and author with 30 years of market entry experience in Europe, Asia and the U.S. Aksenov has been in the cannabis vaping industry for more than seven years. He has created several ventures ranging from branding studios, record labels and media management companies to marketing agencies.

Dumas de Rauly is the scientist. He currently chairs the ISO (International) Standards Committee TC126/SC3 on Vaping Products and the CEN (European) Standards Committee TC437 on Vapor Products. He is also a member of the informal Marijuana Science and Policy Work Group managed by the Colorado Department of Revenue’s Marijuana Enforcement Division and Colorado Department of Public Health and Environment. Dumas de Rauly is also the former president of FIVAPE, the French vaping trade federation, and now serves as the organization’s secretary-general for international relations.

“As chairman of ISO standards on vaping products, I was getting a lot of friends that were coming up to me and asking me what I thought of their vaping products. And when I looked at them, I quickly saw that the products they were using were not adapted to the format of the [cannabis] extract, which is very, very viscous, oily, in some cases, really like molasses,” explains Dumas de Rauly. “I got concerned about the safety issues, started looking into it and … my partners and I decided to create the Blinc Group to bring the wealth of experience we had in nicotine vaping over to the cannabis industry.”

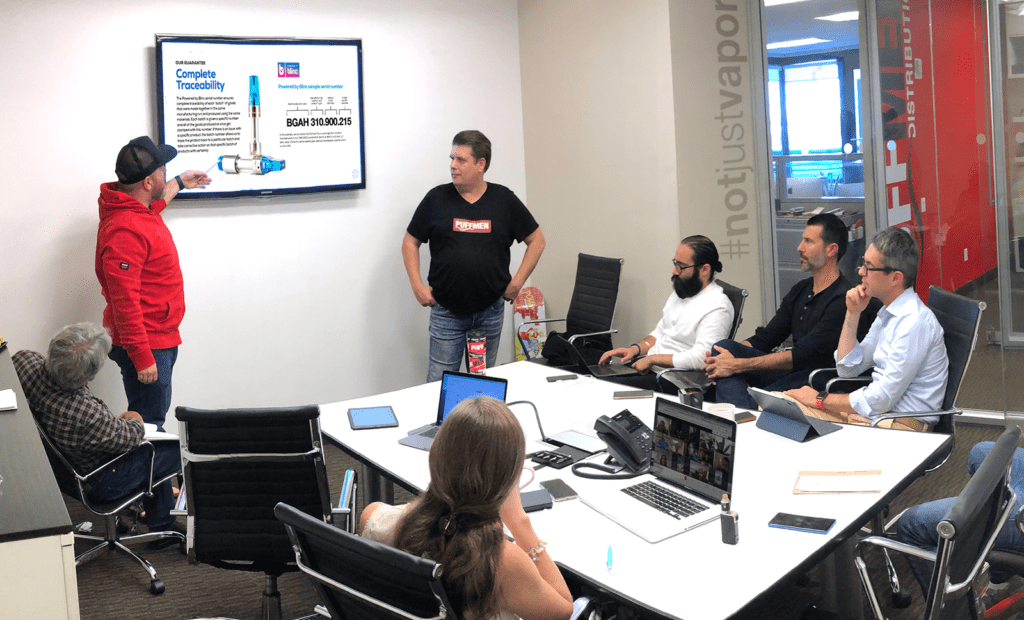

What sets Blinc Group apart from other cannabis industry hardware manufacturers is its involvement in every aspect of the process, from design to sales—what Dumas de Rauly calls “enterprise solutions” or consultative sales. The company doesn’t do sales on a traditional transactional basis. Every Blinc team member gets involved. “We can move along the entire vaping value chain. We have done product formulations for clients; we go through automation with filling and capping SOPs all the way down to point of sale and training,” says Dumas de Rauly. “We train our clients’ salespeople on specific hardware. We really insert ourselves throughout the entire value chain of vaping products in cannabis.”

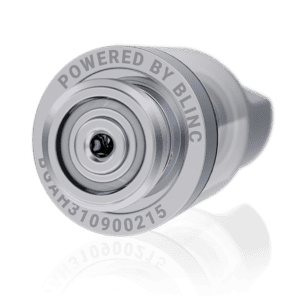

The Blinc Group may be the only cannabis industry vaping hardware manufacturer that controls its entire supply chain. This is important because when a manufacturer orders from a factory in Shenzhen, China, where most vapor hardware is produced, that company has no clue where the raw material is sourced. The factory knows but not the client. Blinc Group sources the raw material suppliers. It then tells the subcontracted factory that those factories need to use the Blinc-sourced suppliers.

“We have an entire audit trail of every single material that comes into the device. That is one very important [differentiator] and one of our biggest differentiators. It also allows us more resiliency and redundancy within our supply chain because we’re not buying just from one factory,” Dumas de Rauly says. “We have four different manufacturers we work with—or assemblers, as we call them because they don’t really manufacture. They assemble products. And when one of them is not available, we can have the same product manufactured by another one because we own all of that supply chain.”

Blinc and you’ll miss it

There is one fundamental reason for controlling the supply chain: safety. Alongside innovation, quality and integrity, Dumas de Rauly says safety is part of Blinc Group’s foundation. It’s the company’s main focus in advocacy as well. For example, recently, the company worked with the U.S. state of Colorado to implement emissions testing in vapor products.

“[Colorado is] the first state in the U.S. that is requiring emissions testing, but that just goes to show that we’re even willing to put barriers in front of our business to make sure the consumer is safe. We have pioneered the use of medical-grade stainless steel in the products instead of using the regular H59 material to avoid any leaching of lead,” Dumas de Rauly explains. “We push our analysis and the control of the supply chain specifically for these reasons. Another example: In a typical 510-threaded cartridge, you have all of the materials that come into contact with the oil inside. Each one of those materials is sent off from each supplier—and we have four suppliers for each material—to undergo testing in an international lab. And given what we find, we adjust that material to make sure that individually, every single piece one of our cartridges will not leach, for example, heavy metals.”

Blinc Group has a large presence in Canada specifically because of the company’s compliance and regulatory stance, according to Dumas de Rauly. He expects the U.S. to adopt a similar type of regulatory framework soon. “People have already started understanding the need for regulations since the EVALI vaping crisis,” he said. “I’m very confident that this year, we’re going to be focusing a lot of our attention on the U.S. market and growing our U.S. presence.”

After Canada legalized recreational marijuana, the country passed the Cannabis Act. It includes some of the most stringent rules for cannabis on compliance and regulation in the world. Batteries, for example, need to be UL 8139 certified. In the U.S., it’s only a recommendation. The certification costs a little more, and the UL process could take anywhere from three-month to six-months, says Dumas de Rauly, but it’s necessary to protect the end user.

“We were the only ones attacking that market with UL-certified products in terms of batteries. We were the only one attacking that market with FDA, CFR21 or CPG21 certifications for our raw material. That was our edge, and that’s why we made such a big impact in Canada in 2020,” says Dumas de Rauly. “As regulation is becoming a little more stringent in the U.S. and after the EVALI scare, those consumers are starting to understand that they need to be paying attention to what’s in the vaping hardware.”

As EVALI soared in the U.S., many believed the vaping industry was dead and the disposable option was a fad. Dumas de Rauly says that, in reality, cannabis accounts for more than 30 percent of the market in some states. Some states with legal medical marijuana allow only the sale of THC vaporizers. This is because contents and strength can be easily regulated in a vaping product. The same is not true for cannabis flower products. He sees the industry growing even more rapidly in the U.S., especially if marijuana is legalized on a federal level.

“The road is going to be bumpy. There is going to be more regulation. We are pushing for more regulation because we want to make sure that our business is sustainable over the next five to 10 years,” he says. “We don’t want to see what happened to nicotine vaping happen to cannabis vaping. We’re really pushing for good stewardship for the industry. We are thought leaders in the space, and we want to be at the forefront of education and making sure that consumers get safe products.”

As the legal cannabis market grows in the U.S., Dumas de Rauly says that the Blinc Group will be growing and continuing to grab more market share as well. He says that the Blinc process is highly developed. It runs like a well-oiled machine. “We have a very strong team,” says Dumas de Rauly. “We have a strong presence. Our processes are well refined. I believe we’re going to be doing very, very good this year.”