The major complaint against the proposed U.S. rules for vape manufacturing is that they took too long.

By Maria Verven

The U.S. Food and Drug Administration published a new set of proposed requirements for tobacco and vape product manufacturers in March 2023 with the goal of ensuring product consistency and ostensibly protecting public health. But vape industry experts say the new rules should have come out years ago. And for most vape manufacturers, it’s simply too late.

The FDA held a public hearing on April 12, and stakeholders can still comment on the proposed rule until sometime this fall before the regulatory agency issues the final guidance. In the meantime, Vapor Voice spoke with several industry experts to gather their perspectives.

Minimizing the risks

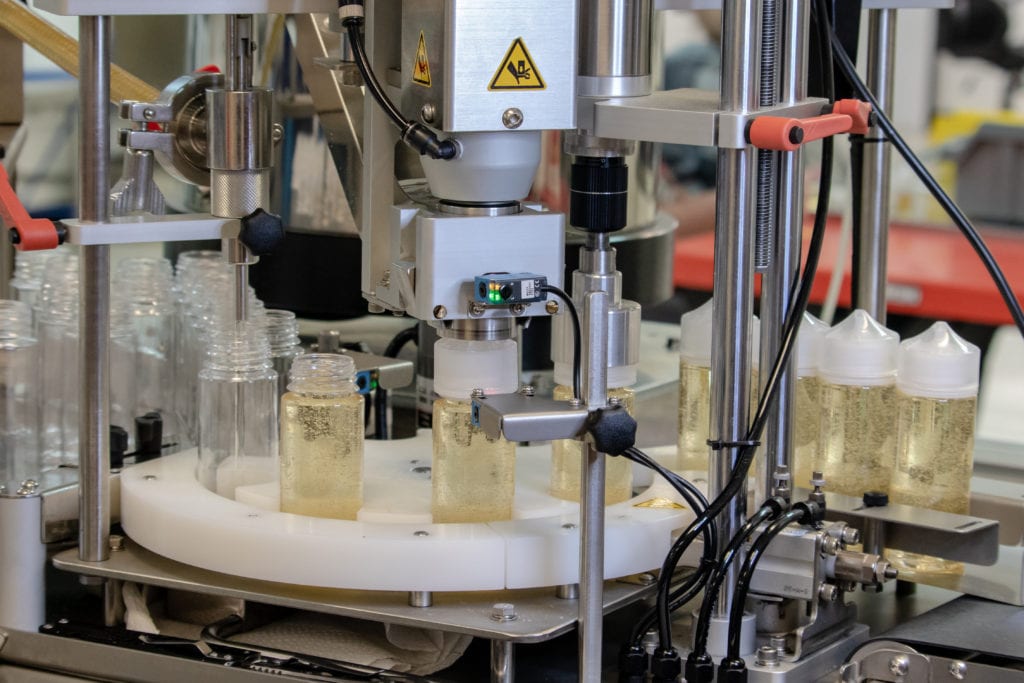

The proposed requirements apply to all manufacturers of nicotine vaping products and tobacco products designed for consumer use, whether complete and sealed in packaging or simply their parts or components. Applied to the manufacture, design, packing and storage of these products, the rules are designed, among other things, to ensure product consistency and prevent contamination with foreign substances.

“While no tobacco product is safe, this proposed rule is intended to minimize or prevent additional risks associated with these products,” said Brian King, director of the FDA’s Center for Tobacco Products. “Once finalized, it would establish requirements for tobacco product manufacturers that will help protect public health.”

Key aspects of the proposal affecting vape manufacturers cover product design and development controls, manufacturing specifications, potential contamination and the traceability of components, ingredients and materials. Any inconsistencies between e-liquid product labeling and the actual nicotine concentrations are also addressed in the proposed rule.

Finally, the rule includes what corrective actions the FDA will take for products that fail to meet these specifications, such as issuing a recall for incorrectly produced products that have already been distributed.

What took so long?

The FDA’s proposed rule was at least 10 years in the making. Sometime in 2012, a group of 13 tobacco manufacturers submitted to the FDA a list of recommendations for good manufacturing practices—a system for ensuring that products are consistently produced and controlled. The following year, the FDA created a public docket to obtain input on the recommended regulations for good manufacturing practices that had been submitted by the tobacco companies.

And in 2017, an expanded group of manufacturers submitted proposals following the FDA’s 2016 Deeming Rule, which brought vaping manufacturers and products under the FDA’s jurisdiction, according to Patricia Kovacevic, general counsel for Cryomass Technologies Inc. A nicotine/cannabis regulatory consultant, Kovacevic has over 20 years’ experience in legal and regulatory affairs.

“Tobacco product manufacturing practices (TPMPs) are not unexpected or new to the industry,” Kovacevic said. “Most reputable manufacturers already have a quality management system in place and design their manufacturing facilities to comply with the general principles of current good manufacturing practices (CGMPs).

“The 2023 proposed rule on TPMPs is consistent with the manner in which the FDA regulates the practices, design and construction of personal hygiene products,” she said. As early as 1969, the FDA established CGMPs for foods as well as dietary supplements, infant formula and the like, added Kovacevic.

This is a positive step in the right direction, both for the industry and the FDA, agreed Azim Chowdhury, a partner with Keller and Heckman LLP. Chowdhury advises domestic and international corporations on regulatory compliance with the FDA, focusing on vapor, nicotine, tobacco product and cannabis/CBD regulation.

“This proposed rule is long overdue,” Chowdhury said. “This proposed rule should have come out years ago following the industry-proposed TPMPs that were submitted back in 2012. The vapor industry in particular has been in dire need of this type of regulation, which can only benefit public health.”

In essence, the principles are not substantially different from other FDA-regulated industries, Kovacevic said, adding that some manufacturers also comply with ISO quality standards, the world’s best-known quality management standards for companies of all types and sizes.

“It’s important to understand that TPMPs do not impose a certain product or manufacturing facility design or even dynamic of reporting,” Kovacevic said. “TPMPs are not prescriptive. They allow great latitude to manufacturers; thus, they should not be a great burden to be implemented.”

As with all CGMPs, the common components are documenting procedures for business operations and outcomes, ensuring that personnel are appropriately trained, work procedures are followed and a document trail is created. This allows manufacturers to design the day-to-day practices for maintaining their equipment and facilities to maximize product quality, cleanliness, consistency and employee safety.

TPMPs and PMTAs

While the general reaction to the FDA’s proposed rule is positive, frustrations remain that the FDA has already banned most vaping manufacturers through the premarket tobacco product application (PMTA) process. Large manufacturers (with 350-plus employees) will be subject to the TPMP rule as soon as it is finalized, according to Chowdhury. Smaller companies have four years after the effective date to meet the requirements.

“However, the question is will the small vape industry even be around in four years?” Chowdhury said. “The way things are going with the PMTA process and FDA enforcement, it seems that only the larger players will survive to see the implementation of this rule.”

“As it became evident from the vast number of PMTAs that were denied or refused to file, small manufacturers and even some of the large ones did not meet FDA’s expectations regarding premarket review of vaping products and are consequently out of business for now,” Kovacevic said.

“The vaping industry has tried in vain for more than a decade to work with the FDA on sensible manufacturing standards only to be ignored while the agency recklessly vilified nicotine vaping,” said Gregory Conley, president of the American Vaping Association. “While the FDA’s proposed requirements are a step in the right direction, the larger issue of the PMTA process disproportionately affecting smaller manufacturers and limiting market diversity must be addressed.”

“The FDA needs to strike a balance between ensuring public health and maintaining a diverse and competitive market,” he said. “Without PMTA reform, there won’t be many companies left to be impacted by this proposed rule. It’s highly likely that vaping product manufacturers that received marketing orders under the PMTA pathway already have rather robust quality systems. So, complying with TPMPs will not represent a meaningful burden to them.

“These regulations do not appear to differ a great deal from what would already be contemplated in a PMTA. But if the FDA’s Center for Tobacco Products does not reform itself, the real-world impact of this rule will be small, as companies with PMTAs will have no issue meeting just about any standard the FDA issues,” he said, adding that he wouldn’t recommend any manufacturer put themselves on the FDA’s radar at this junction.

Kovacevic agreed. “Compliance with TPMPs, when effective, should not require a massive effort for responsible manufacturers, who by now should have a robust quality management system,” she said.

Monica Schick, CEO and regulatory consultant with North Guide Solutions, predicted that the new rules could impact the industry financially. Smaller companies that are holding onto their market share with the rise of illicit products might need to increase their price points to add quality processes and/or testing requirements, according to Schick.

“My concern is are we bringing out the cart when we are sending the horse to slaughter? With illicit products still being marketed and sold and open systems getting continuously MDOed [marketing denial orders from the FDA], what will be left to hitch this cart to?” she asked. “I would like to see this as FDA’s attempt to work with the industry and possibly see some increase in the number of legal products on the market.”

What about foreign manufacturing?

The FDA’s new regulations will also apply to Shenzhen and other foreign-based e-cigarette manufacturers, although just how they will exercise enforcement is in question as the FDA currently doesn’t conduct regular foreign tobacco product manufacturing site inspections.

“Unlike domestic manufacturers, this rule does not require foreign manufacturers to register their establishments, submit a product list or be subject to regular biennial inspections,” Chowdhury said. “However, FDA’s unified agenda of upcoming rulemakings indicates the agency may soon propose another rule that extends the Tobacco Control Act’s registration and product listing requirement to foreign establishments,” he said.

The TPMP rule also highlights the FDA’s existing authority under Section 801(a) of the Federal Food, Drug and Cosmetic Act to refuse the importation of tobacco products that are manufactured, processed or packed under unsanitary conditions, are adulterated or misbranded and/or are forbidden or restricted in sale in the country where they were produced or exported, Chowdhury explained.

Chowdhury said he doesn’t believe the FDA has ever exercised its authority under this provision to deny entry of imported vapor products, such as open-system devices or nontobacco-flavored vapes that are prohibited from domestic sale in China, as this would require the agency to evaluate imported tobacco products not only with respect to the FDA’s own rules but also on the importing country’s applicable laws and regulations. That could prove to be highly inefficient and impractical.

“Furthermore, provisions concerning unsanitary conditions and adulteration/misbranding suggests that the FDA’s overall intent may be to control the quality of tobacco products rather than the specific legal status of tobacco products in their country of manufacture,” he said. “That said, members of Congress, public health groups and even Big Tobacco have been pressuring FDA to find a way to prevent illegal and counterfeit disposable vapor products from continuing to enter the country.

“The TPMP rule could be highlighting that FDA already has the ability to accomplish this.”

Final ruling could take years

A final rule could take at least a year or more. First, the FDA needs to address all the comments from industry stakeholders. And even after that, it’s likely the final rule will be similar if not outright identical to the proposed rule, predicted Kovacevic.

Chowdhury expects that thousands of comments will be submitted over the next six months, which the FDA will need to review carefully before finalizing the rule. “All in all, this rule will likely take at least one [year] to two years to become final. While it won’t directly impact pending PMTAs, companies should be reviewing this rule carefully and bolstering their existing practices to ensure compliance,” he said. “We now know what FDA expects.”

“It is disappointing, but not at all surprising, that the FDA would wait to propose these regulations until it had already committed itself to banning 99.99 percent of the vaping market,” Conley said. “Our recommendations for the FDA include reconsidering the PMTA process, as its current review standards will shutter most legally operating manufacturers.

“We also want the FDA to focus on how to support smaller manufacturers that are committed to producing high-quality, compliant products. The millions of Americans who rely on vaping to stay off cigarettes could benefit from the FDA’s proposal but only if the agency stops thumbing its nose at its critics and starts to regulate the category in good faith.”

The original “Vaping Vamp,” Maria Verven owns Verve Communications Inc., a public relations and marketing firm specializing in the vapor industry.