Numerous small changes come together in possibly the most reliable and consistent pod system ever created.

By Mike Huml

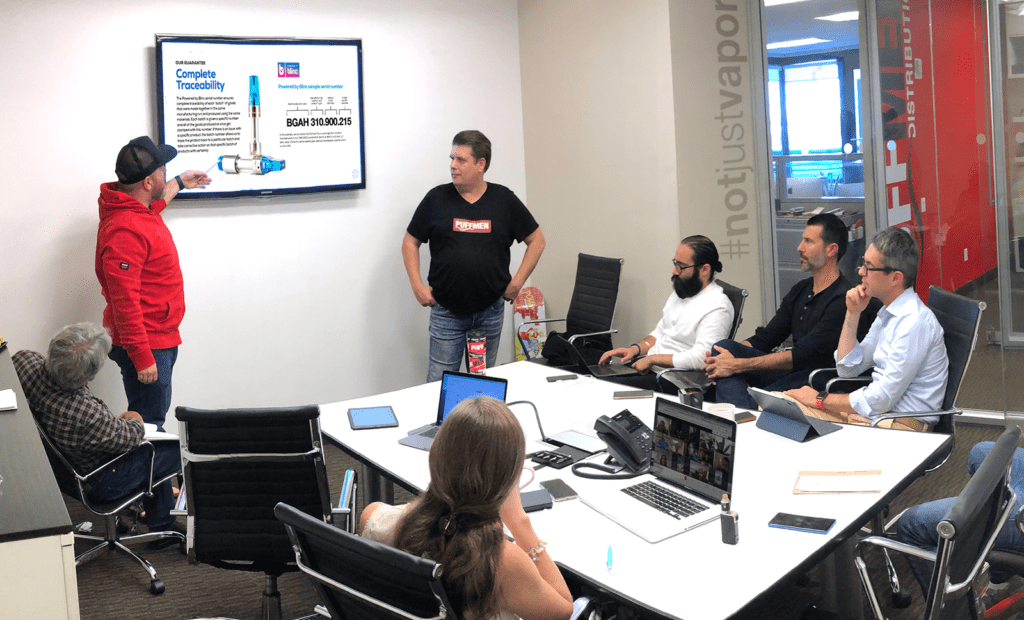

The FEELM Air pod system from Smoore boasts a plethora of groundbreaking innovations. From safety to performance, the FEELM Air comes with a laundry list of improvements over past iterations of pod systems. As the largest vapor manufacturer in the world, Smoore has poured resources into refinement of its technologies to produce a near-perfect pod system.

The FEELM Air is a closed pod system, so each 2 mL pod is disposable. The pods are held in the battery section with strong magnets, and there truly isn’t much more to speak of concerning operation. The simplicity is a huge benefit for those who are seeking a no-hassle vape experience. There is no airflow adjustment, no power adjustments and no buttons whatsoever. The FEELM Air is activated by airflow to more closely replicate the sensation of smoking.

Further, Smoore has incorporated the “world’s smallest linear motor,” which not only provides haptic feedback when a pod is connected or disconnected but also vibrates throughout each drag. This acts as confirmation that the pod is firing since there is no button to press but also gives a more turbulent feel to each drag that anyone accustomed to smoking will be familiar with. Dubbed “shockwave mode,” the vibration feature only consumes power equivalent to two puffs throughout a single battery charge cycle. While shockwave mode may be convenient for some, the vibration is sure to turn some people off, and as such, it would have been prudent for Smoore to incorporate an inconspicuous touch-sensitive button to toggle shockwave mode on and off.

Aside from the inability to disable shockwave mode, the FEELM Air has no other issues and offers quite a bit in the way of innovation and refinement. At 7.8 mm, it’s the thinnest pod system available, making it great for taking out and about. It fits in pockets and pocketbooks easily, and it never leaks thanks to further improvements in the pod structure. Smoore uses “puzzle leakage-proof technology” and an absorption layer within the heating element to eliminate leaking.

The juice flow channels are narrow enough that surface tension keeps condensation from backing up, and the absorption layer re-wicks the liquid back into the ceramic heating element. It works extremely well as the FEELM Air doesn’t leak when stored or stowed, doesn’t cause spitback even when multiple drags are taken in rapid succession and never produces dry hits due to slow wicking. By Smoore’s estimation, this design reduces leaking of any kind by 237 percent.

The battery life of the FEELM Air is good and lasts through approximately half of a single 2 mL pod. By only firing at or around 6 watts, a smaller, thinner battery is adequate. The device is charged with an included USB-C cable that is capable of fully charging the battery in about 15 minutes. Additionally, the FEELM Air can be used while it’s charging, reducing the already low downtime to near zero. A constant power output of 6 watts may seem a bit weak, but thanks to the design of the heating element, it produces vapor equivalent to other pod systems that fire between 12 watts and 15 watts.

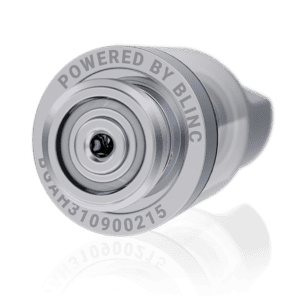

Each heating element comprises seven different layers, each for a different purpose. In short, the heating element in each pod improves flavor, efficiency, safety, consistency and leakiness. Lower power, a more efficient heating element and a more uniform heating surface reduce exposure to heavy metals, ketones and aldehydes by 80 percent. A separate layer uses Smoore’s “flavor-lock” technology to increase flavor release by 33 percent. The smaller vapor particles produced by the ceramic heating element are also conducive to more efficient nicotine absorption, so each pod lasts a bit longer.

It’s clear that Smoore has put significant resources toward improving the vaping experience provided by its pod systems, but how does it affect the end user? After all, heavily marketed features don’t always translate to better products. In the case of the FEELM Air, there is definitely a marked improvement in consistency over many other pod systems, but given the nature of innovation and refinement, don’t expect mind-blowing improvements to the established order. The improvements are subtle but effective, and the FEELM Air may be the most user-friendly device currently available, particularly for those with absolutely no knowledge of vaping.

Case in point: There is a lot of literature pertaining to the “three innovations” and “seven breakthroughs” implemented in the design and creation of the FEELM Air. A new film designed for the heating element is 40 times thinner than that of the previous generation. The new ceramic coil is also 30 percent thinner. Seven layers of composite heating film are made from medical-grade materials and are created using a nanoscale vacuumed film-forming technique to produce a microporous bionic structure.

The seven-layer heating element includes a nanoscale protection layer, a microporous flavor lock layer, a nano silver electro layer, a superabsorbent lock layer, a precise composite heating layer, a temperature control layer and a porous thermal resistance layer. These layers in tandem with the upgraded capillary structure incorporated into the pod itself contribute to the aforementioned reduced leakage and improved consistency. What does all of this actually mean?—It vapes good.

However, even given the above information and more, there are still a few unknowns. What is the battery capacity? What is the nicotine strength of the e-liquid? Even with a lot of marketing, some basic information is omitted—but this is information only an experienced vaper would value. A new user probably wouldn’t care that the FEELM Air has a 100 mAh battery while Pod System B uses a 150 mAh battery.

How does one measure “flavor release” to determine that it’s increased by 30 percent? And why would that matter for a pod that can’t be refilled? Will Smoore produce less expensive pods due to not needing as much flavor extract, or will the flavor be stronger than usual due to this flavor increase while the same e-liquid is used? How many of the claims benefit the industry or the user, and how many are just big words to use as filler for a brochure? With all the apparent detail provided, it’s suspicious that basic information was left out—or at least it would be if the FEELM Air was a poor product.

Whatever Smoore is doing, it’s working because the FEELM Air is probably the most consistent pod system currently available. After significant usage, there was no spitback, no misfires, no leaking, no dry hits and no kind of any other issue. Each subsequent drag was identical to the previous one, and the flavor was admittedly good. It wasn’t leaps and bounds beyond other pod systems, but it was consistent, voluminous and flavorful enough.

Operation couldn’t be simpler or more straightforward. Perhaps the reason for the lack of information that vapers are used to having access to (such as battery capacity) isn’t needed. For someone brand new to vaping, the FEELM Air requires virtually no explanation. Insert the pod; start vaping. Plug it in when the battery dies, and replace the pod when it’s empty. There’s no fiddling, no settings, no troubleshooting problems. It’s simple, and it works consistently.

While the marketing for the FEELM Air seems a bit excessive and overly technical, Smoore clearly wants the industry and consumers to know the nature of the work they’ve been doing to improve the vaping experience and safety. Just the peace of mind brought about by knowing that the efficient, 6 watt output and seven-layer heating element are working to further reduce any harm caused by vaping or technical shortcomings may be enough to make the sale. The diminutive size is also a huge positive, but the vibration feature borders on gimmicky rather than useful.

Tactile confirmation of automatic switch activation may provide an extra layer of protection against accidental firing, but that’s largely a solution to a problem that hasn’t existed in any meaningful way since 2010 when automatic switches would fire if music was played too loudly. Still, it’s a small complaint considering that the package as a whole is providing one of the best vape experiences for a pod system on the market.

The FEELM Air from Smoore takes refinement to a new level. A multitude of small changes come together to provide possibly the most reliable and consistent pod system ever created. While everyday use won’t knock anybody’s socks off with massive clouds or tear-jerking flavor, it’s definitely among the best options for new users and smoking converts. As the vapor industry delves deeper into the era of refinement, these sorts of innovations will become commonplace. The average user won’t necessarily care about what each of the seven layers in the heating element actually do, but everyone will benefit from more consistency and, therefore, safety.