One of the world’s most successful vapor brands, Smok, has set its sights on the OEM/ODM sector as well as the marijuana and cannabidiol industries.

By Timothy S. Donahue

Change is coming. One of the world’s largest vapor hardware manufacturers is expanding into new markets. Shenzhen IVPS Technology Company (Smok) is growing its OEM/ODM division as well as strategically focusing on the the marijuana (specifically THC) and cannabidiol (CBD) markets, according to Luna Wang, general manager of Smok’s ODM and CBD division.

In early 2018, Smok made the OEM/ODM market the emphasis of its new approach toward future growth, says Wang. The company was already cooperating with several major tobacco companies and e-liquid manufacturers, including several CBD and THC oil manufacturers. Smok has long been one of the most successful hardware manufacturers in the vapor industry; however, after watching the rapid growth of the THC and CBD markets, Wang says Smok needed to place a stronger concentration on those industries.

“We have been a force in the vapor industry, and this new focus is very important to the future of Smok,” says Wang. “It can have a very positive effect on further promoting Smok’s product quality and industry recognition.”

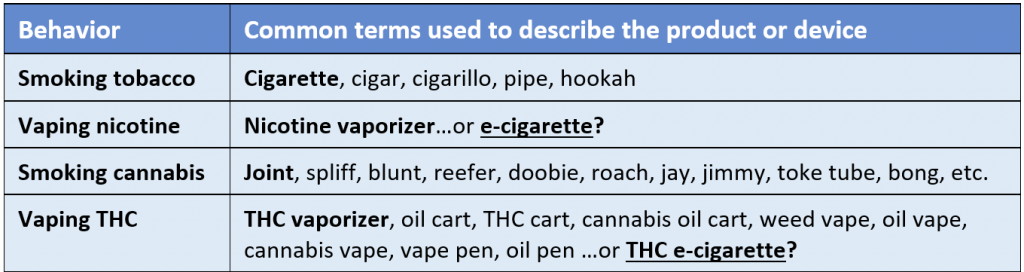

ODM stands for original design manufacturing, and OEM refers to original equipment manufacturing. An OEM company designs and builds product according to its own specifications. The company then sells the products to another company or agency, which is responsible for its distribution. An ODM company, however, uses the specifications of another company—its client—when designing and building a product.

Wang says that the decision to move into the CBD and THC markets was easy. After all, Smok was already one of the leading brands of open systems and had a deep understanding of vapor hardware. The company was also responsible for several industry-changing innovations in both tanks and devices.

“We have produced several of the bestselling products in the industry,” says Wang. “Smok has a very broad and deep understanding of the research and development trends. “We are now preparing to open a new factory that will meet current good manufacturing practice [cGMP] standards. It will also be capable of fulfilling high-level production requirements with stringent quality-control [QC] standards in order to satisfy our clients’—both new and existing—needs. We have established this new factory in order to meet the dust-free workshop requirements of cGMP standards, and we can guarantee that we will continue to produce first-class hardware.”

Smok’s new 20,000-square-meter (215,278-square-foot) factory will house approximately 2,000 employees. In its early stages, the factory will work with clients who have similar product and design concepts as the Smok brand, according to Wang. Smok’s new division will produce both open and closed systems that will be able to be used with various mediums. From an R&D perspective, Smok expects to continuously introduce new products that can reach the higher level of standards that comes with years of R&D experience and the history of successful products that Smok has brought to the market.

“We believe that the trend towards future products will be devices that can be used for both nicotine salts as well as CBD/THC oils,” says Wang. “There will be various open and closed systems because our clients all have different needs and expectations. Smok has already produced products for the CBD/THC market that have found significant success. We expect to build on that trend.”

Founded in 2010, Smok started out producing 510 stick batteries, 510 atomizers, cartridges, cartomizers, and other primitive e-cigarettes and components. In those days, there were countless e-cigarette manufacturers making cheap products. What started with only seven employees in a 2,600-square-meter building has grown into a power player with about 5,000 employees and 20,000 square meters of combined office/factory space (not including the soon-to-be-finished factory).

Smok found its niche by offering quality products at reasonable prices. The company secured its success by bridging the gap between expensive high-end devices and the borderline-defective inexpensive devices flooding the market. Smok wanted to maintain affordable price points while maintaining a portfolio of high-quality, reliable products.

From the beginning, Smok has been improving upon successful trends. It was among the first to offer longer-lasting batteries, multiple sizes of cartomizers and a variety of LED colors. It was the first to introduce dual-coil cartomizers. As the name suggests, these cartomizers contain two separate heating elements that increase the surface area for better flavor and vapor production while reducing the chance of a burnt flavor. The dual-coil cartomizers were a big factor in Smok’s success.

As the vapor industry has grown, so has Smok. The company offers everything from less expensive versions of popular products to its own new, innovative products. When clearomizers became the rage, for example, Smok not only improved the product and its performance but also reduced production costs through its growing manufacturing skill set. The company then improved upon the basic clearomizer design by offering bottom-coil clearomizers and tanks. Bottom coils are now the industry standard.

Due to the varying characteristics of how CBD/THC oils are vaporized, Smok intends to produce its own as well as ODM products that can help its clients achieve specific desired results under the multitude of mediums used in producing the oils and concentrates. “For example, different marijuana strains have different terpenes. This means that only ODM products can maintain the best and most beneficial taste profiles,” says Wang. “Therefore, our CBD/THC products will be part of Smok’s OEM/ODM business because this is the best way to give our clients the high-quality products that they have come to expect from Smok.”

Several studies have shown that terpenes work with cannabinoids (like THC and CBD) to enter the bloodstream more easily, thereby lowering the blood-to-brain barrier. Terpenes help users feel more or less of a cannabinoid’s effects. Some terpenes can increase the potency of a THC high while others can mitigate it, according to Wikileaf.com. Numerous studies have shown that terpenes play a role in how the THC/CBD users feel. Terpenes can be likened to how hops influence an India pale ale.

Smok also maintains strict control over the quality of its raw materials and has specific standards in the procurement of its raw materials, according to Wang. She says that there must be “very high standards in the QC area throughout the entire production process. This is the only way to reduce a product’s defective rate to a minimum.”

In order to meet its goals, Smok has also hired a new team to help run its enhanced ODM/OEM divisions, including THC and CBD, according to Wang. “We have spent a lot of time and a lot of effort on securing some of the best minds in the industry in order to help our clients meet their various goals of quality and performance in their products,” she says. “The most important part of being a high-end OEM/ODM manufacturer is the quality of the staff that goes into producing the products. We believe we have created the strongest team in order to meet these goals.”

Moving forward, Wang says she expects the THC and CBD markets to explode over the next two years. She hopes that Smok’s products can be an influential factor in that growth and that Smok can achieve the same level of brand awareness as it has in the e-cigarette industry.

“Smok has been manufacturing quality, affordable vapor hardware since the early days of vaping,” says Wang. “The company creates products catering to vapers of every level, from beginners to enthusiasts. It has improved upon popular trends and created several of its own. We expect to carry on that tradition with our much-improved OEM/ODM division, including our service to the THC/CBD industries.”